OEE software

OEE (Overall Equipment Effectiveness) is an essential performance indicator in the world of industrial production. It makes it possible to measure the overall efficiency of equipment by taking into account three main variables: availability, performance and quality. Monitoring OEE is vital to identify opportunities for improvement and to establish optimized production processes.

Optimize your industrial performance in three steps

OEE software collects real-time machine data, particularly downtime and duration, and makes it easier to identify downtime causes with intelligent recommendations. It also allows you to analyze data on the availability, quality and performance of your plant. With an intuitive interface, you can quickly identify sources of loss and take corrective action to improve productivity.

Transform Your Production Management

Our OEE software offers a complete solution for production monitoring, simplifying data collection, performance analysis and quality improvement. Thanks to advanced functionalities, it allows operational teams and managers to be more involved in monitoring the main causes of loss of efficiency and in actions to improve industrial performance. OEE software helps you maximize productivity and maintain high quality standards, thus contributing to the success of your transition project to Industry 4.0 .

Presentation of the OEE Monitoring Dashboard

Tell your story with pictures

Deployment and Integration of OEE Software: Optimization of Industrial Processes

Deployment and Integration

Implementing OEE (Overall Equipment Effectiveness) software within your company is a strategic approach, designed to be simple, agile and efficient. We offer you adaptive and scalable solutions, guaranteeing perfect integration with your industrial processes.

Our team supports you every step of the way:

- Facility :

OEE software is installed on your systems, with technical support from Digital Factory if necessary. We ensure a smooth implementation, whether in SaaS mode or on a local server, depending on your needs.

- Configuration:

Customize the software so that it adapts perfectly to the specificity of your processes and your industrial environment. This step ensures seamless integration with your current practices.

- Training:

Your teams will be trained to master the software and to fully exploit its potential. This training aims to strengthen the autonomy of your employees in the daily use of the tool.

- Integration:

OEE software is designed to integrate seamlessly with your existing systems. This ensures optimal coordination and efficient centralization of data, a key element of your digital transformation.

Our support offer ensures a smooth and efficient transition for your business, with the implementation of a tailor-made strategy based on your objectives and your industrial environment.

OEE Software Features for Different Types of Users

OEE software is designed to meet the diverse and complex needs of industries across different sectors. Offering a user-friendly interface and a comprehensive suite of features, our solution is suitable for different types of users, from production operators, team leaders, production managers and system administrators. Here's how OEE software makes every role in your business easier:

| Functionality | Description |

|---|---|

| 📝 Data Entry | Simplified interface for rapid identification of the cause of stoppages. |

| 👁️ Intuitive Interface | Designed for ease of use, even for those with limited computer experience. |

| ⏱️ Real-Time Tracking | Allows operators to monitor the current performance of their machine or production line. |

| 🔔 Alerts and Notifications | Informs operators of anomalies or shutdowns, enabling rapid response to minimize downtime. |

| 💡 History-Based Recommendation System | Intelligent recommendations are provided to optimize operator performance, based on analysis of historical data. |

| 🆘 Help and Support Center | Access to a comprehensive FAQ, interactive tutorials and an incident reporting system for ongoing support. |

| Functionality | Description |

|---|---|

| 📊 Dashboard Management | Customize dashboards to display relevant KPIs for their specific team. Integration with Business Intelligence tools like Power BI for the creation of customizable and scalable reports. |

| 🔍 Performance Analysis | Tools to analyze team performance trends, identify bottlenecks and opportunities for improvement. |

| 📈 Tracking Improvements | Functionality to monitor the impact of actions implemented on production performance, allowing continuous evaluation of the effectiveness of the measures taken. |

| Functionality | Description |

|---|---|

| 🌐 Global View | Access to overviews of the performance of all lines and machines, enabling effective management and supervision. |

| 📊 Advanced Analysis | Analytics tools to assess overall performance, identify trends and plan strategic improvements. |

| Functionality | Description |

|---|---|

| ⚙️ Configuration and Personalization | Capabilities to configure and customize software based on specific business needs. |

| 🔒 Security Management | Managing user access and authorizations |

| 🔗 Integration with other Systems | Ease of integration with other business systems such as ERP, MES and SCADA. |

| 🔧 Support and Maintenance | Access to diagnostic and support tools to ensure efficient maintenance and quickly resolve issues. |

OEE Software Use Cases and Testimonials

Context

In a context where more than 50 manufacturing industries were looking to improve their OEE (Overall Equipment Effectiveness) and reduce unplanned downtime and scrap, OEE software proved to be the ideal solution.

Discover a case study in the pharmaceutical sector.

Solution

These companies have adopted our Plug & Play tool, designed for easy and quick integration in just a few clicks. Thanks to intuitive interfaces, our solution easily connects to various business software, ensuring smooth collection of ERP and MES data . Our tool stands out for its advanced functionalities and its adaptability to the specific needs of each industrial environment.

Additionally, our tool offers the ability to create advanced reports for managers through seamless integration with Power BI.

In this video, you will discover a Dashboard connected to production line data, available in desktop and mobile format, which will allow you to analyze the OEE (Overall Equipment Effectiveness) in real time.

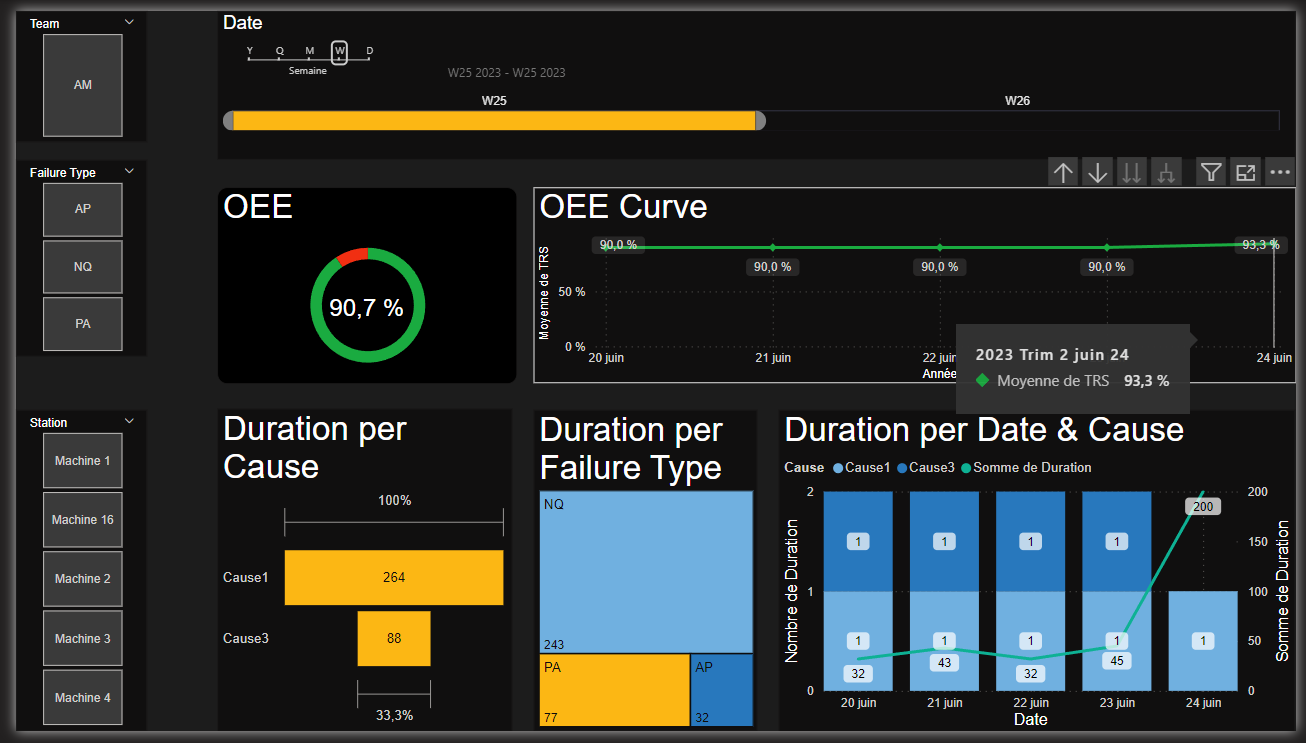

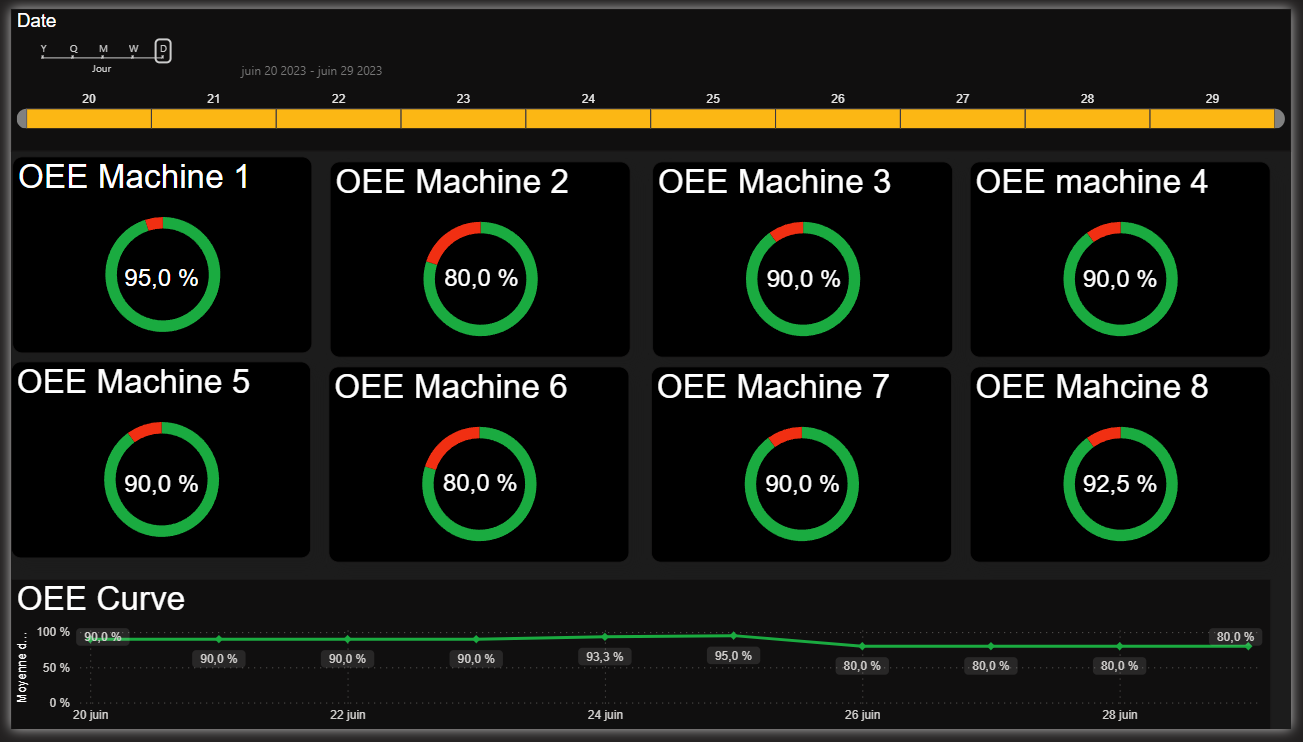

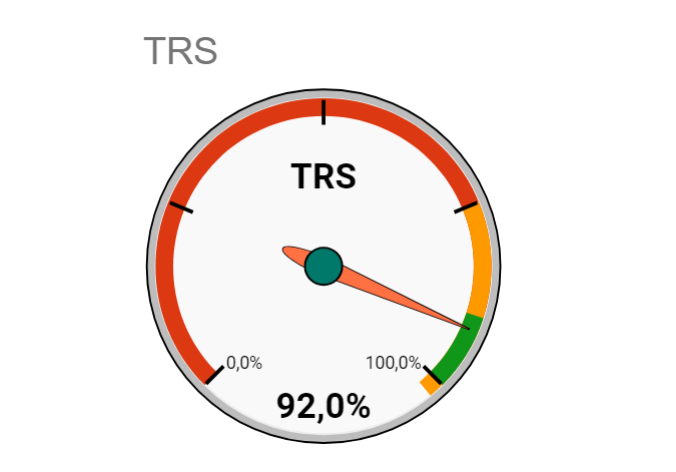

Below are screenshots showing different tracking done using this example dashboard:

Please note that these examples are specific to a particular industrial environment. For your own environment, custom dashboards will be created based on your specific needs.

Global OEE dashboard, to monitor production ligne OEE as well as causes and types of failures, dynamically filterable by team and machine.

Chart to monitor OEE per machine for a given period.

Dashboard to monitor OEE curves per machine.

Monitoring of production batches and loss of performance by team .

Implementation

- Quick Setup:

Simple installation and suitable for enterprise environments such as Microsoft 365 or Google Workspace.

- Connection to Production Data:

Data integration for analysis via interactive dashboards.

- Real-Time Analysis:

Rapid identification of optimization opportunities through analysis of production data.

Results

After several months of using OEE software, companies have noticed:

- Improved OEE:

Significant increase from 70% to 85% on average.

- Reduction of Unplanned Downtime:

Reduction of 23%, thus optimizing production time.

Testimonials

Feedback from our customers underlines the added value provided by the OEE software and Digital Factory's commitment to offering solutions that significantly transform production processes.

FAQ about OEE Software and its Implementation

Q1: What is OEE software and what is it used for?

OEE software is a production performance monitoring solution that integrates essential KPIs, including OEE. It allows you to monitor production quality, identify the causes of rejects and stoppages, and improve the efficiency of the production line.

Q2: What are the main features of OEE software?

The OEE software includes a production dashboard, data entry sheets to record production campaigns, quantities of good, reworked and scrapped parts, as well as production stoppages. It also offers batch tracking charts, Pareto charts for root causes of scrap and downtime, and pivot tables for custom analysis.

Q3: How does OEE software work?

To use OEE software, follow these simple steps:

Enter the line stations, causes of rejects and causes of stoppages into the software.

Populate databases by recording production campaigns, stoppages and scraps. Data can be collected automatically from your ERP or MES software, or using a module to install on your machines. Stops are qualified by the operator or via an intelligent stop identification system.

View and analyze the performance indicators of your production line on the dashboard.

Implement corrective actions to improve the performance of your equipment.

Q4: How can OEE software simplify production management?

OEE software simplifies production management by automating data collection, providing clear visual analytics, and quickly identifying critical issues. It allows corrective measures to be taken more quickly by prioritizing the treatment of major causes of performance loss, which improves productivity and production quality in an efficient manner.

Q5: Is OEE software compatible with other existing systems?

Yes, OEE software can be integrated with other existing systems such as ERP, MES, SCADA, etc. It facilitates the visualization of KPIs and the analysis of improvement actions, offering a complete solution for monitoring production performance.

Q6: Where can I get OEE software and how to install it?

A plug and play template is available on the Google Sheets and Excel editors which will help you start your tracking and further understand the different aspects of this method, this template is available in the Plug & Play tool library . Tailor-made SaaS solutions or to be deployed on your local servers may require development and integration time varying between 3 and 6 months. Visit our support offer page to find out more and contact us for more precise pricing.

Q7: What are the advantages of the support offered?

The support offered helps you implement a complete solution to integrate data from your existing systems, simplifying the visualization of KPIs and the analysis of improvement actions. You can save time and resources while focusing on improving your production performance.

Q8: What is the OEE software integration time?

Onboarding time depends on your specific needs and system requirements.

Tailor-made SaaS solutions or to be deployed on your local servers may require development and integration time varying between 3 and 6 months

For any further questions or support requests, please do not hesitate to contact us.

Q9: How to choose a good TRS software?

To choose a good TRS (Synthetic Rate of Return) software, it is important to consider several essential criteria: ease of use, the ability to provide detailed reports, integration with your existing systems, and the technical support offered. To find out more visit Top 8 OEE Tracking Software in 2024: Production Efficiency - Section: selection criteria for OEE software)

Any questions?

Contact form

blog posts

View all-

How to reduce the administrative costs of a com...

Introduction to Business Cost Reduction Reducing business costs is essential to maximizing profitability. Accounting, logistics, human resources: the tasks involved are essential, but also costly and time-consuming. However, it is...

How to reduce the administrative costs of a com...

Introduction to Business Cost Reduction Reducing business costs is essential to maximizing profitability. Accounting, logistics, human resources: the tasks involved are essential, but also costly and time-consuming. However, it is...

-

Improve your project management with the Kanban...

Introduction Businesses are facing unprecedented challenges when it comes to project management. Client expectations are rising, deadlines are shrinking, and project complexity is constantly increasing. Faced with these challenges, traditional...

Improve your project management with the Kanban...

Introduction Businesses are facing unprecedented challenges when it comes to project management. Client expectations are rising, deadlines are shrinking, and project complexity is constantly increasing. Faced with these challenges, traditional...

-

How to boost innovation?

Introduction Innovation is no longer a simple competitive advantage: in a context marked by the constant evolution of technologies and customer expectations, also with the acceleration towards industry 4.0 ,...

1 commentHow to boost innovation?

Introduction Innovation is no longer a simple competitive advantage: in a context marked by the constant evolution of technologies and customer expectations, also with the acceleration towards industry 4.0 ,...

1 comment