The application of advanced robotics in industry

Introduction

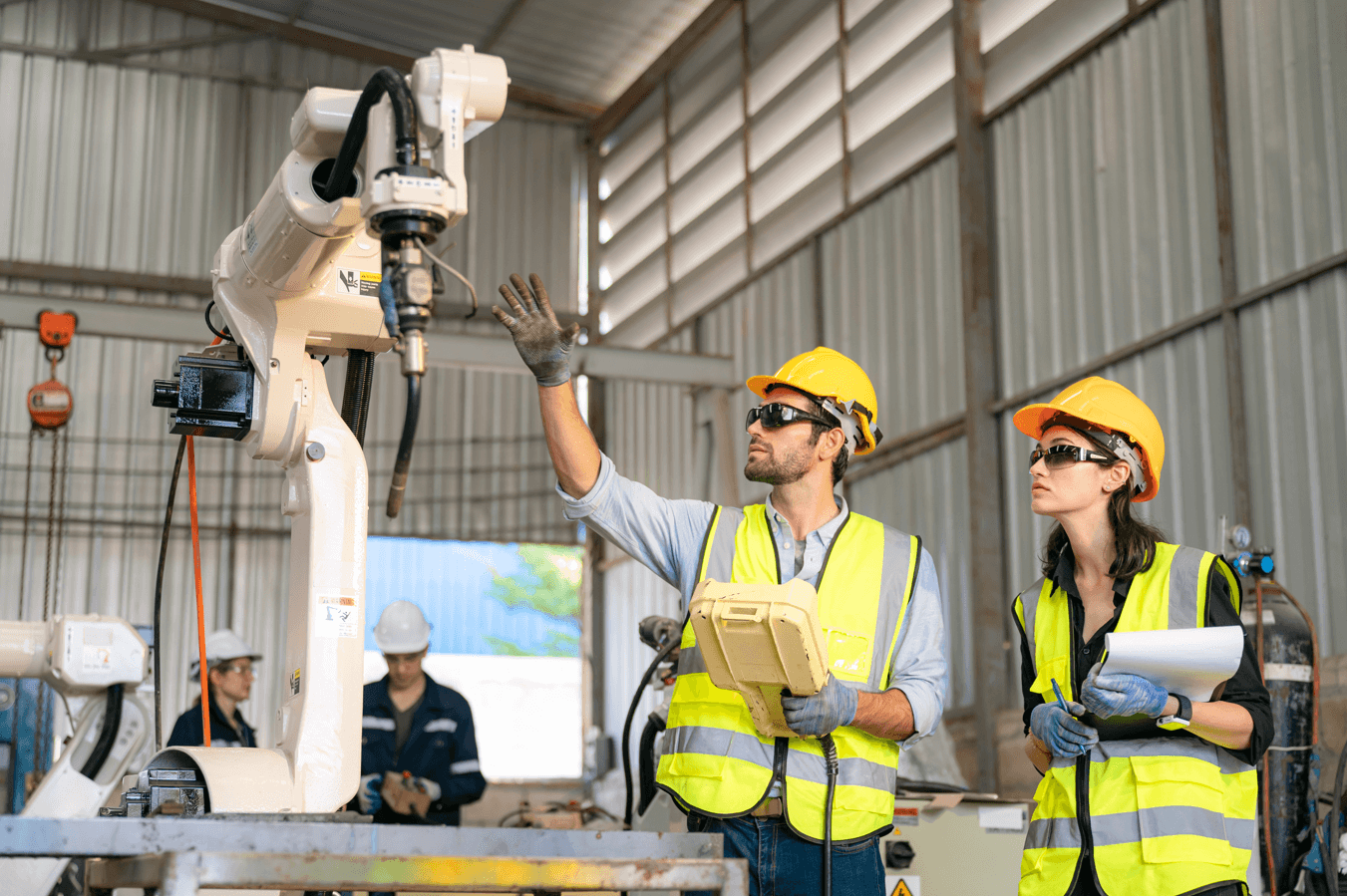

Industrial robotics represents today a fundamental pillar in the automation of production processes. The integration of advanced robots in manufacturing lines is an omnipresent reality, which is redefining industries around the world. This transformation, fueled by dazzling advances in technology and innovation, marks a new era in industrial production. Robots, once simple programmable tools, have become autonomous key players in the optimization of productivity, precision and safety, and are the first levers of any company seeking to make the transition to Industry 4.0 .

History and Evolution of Industrial Robotics

The history of industrial robotics is a fascinating chronicle of progress and innovation. The first industrial robots, introduced in the 1960s , were simple mechanical devices designed for repetitive tasks. Over time, these machines evolved into complex systems, capable of great precision and flexibility.

Technological evolution has played a crucial role in this transformation. Advances in electronics, computing and materials have enabled the development of more efficient, safer and more versatile robots. The advent of artificial intelligence and machine learning has paved the way for robots that can learn and adapt, marking a decisive turning point in industrial automation.

This development has had a profound impact on industrial production. Robots have made it possible to manufacture complex products at a scale and precision previously unimaginable. In addition, they have contributed to improved workplace safety by taking over dangerous or repetitive tasks.

Principles of Industrial Robotics

Industrial robots are distinguished by their design and operation. At the heart of these machines are several key components: mechanical systems for movement, sensors for perception, and control units for data processing. These components work in harmony to accomplish tasks with remarkable precision and efficiency.

Programming industrial robots is another essential facet. It involves the use of specific languages and interfaces that dictate the robot's movements and operations. Programming can range from simple tasks to complex sequences that require careful planning and coordination.

Robots in industry come in a variety of forms, each tailored to specific applications. From articulated robotic arms to autonomous mobile robots, each type has unique features suited to different production environments. This diversity allows for customized integration of robots into various industrial processes.

Applications of Robotics in Different Industrial Sectors

Robotics has revolutionized many industries, each leveraging its benefits in unique ways. In manufacturing, robots play a central role in automating assembly lines, enabling faster, more accurate, and higher-quality production. They are particularly effective in repetitive tasks, where accuracy and consistency are essential.

In assembly and logistics, robots have transformed operations by delivering unmatched speed and precision. They handle and transport materials, assemble components with extreme accuracy, and perform quality control tasks. This automation reduces human error, speeds up production, and lowers costs.

Robotic innovations are also evident in specific sectors such as automotive, aerospace and electronics. In the automotive industry, for example, robots perform a variety of tasks, from painting to assembling complex parts. In aerospace, they are used for high-precision operations, such as drilling and riveting aircraft components. In electronics, robots facilitate the assembly of small components, contributing to the miniaturization and increasing complexity of devices.

Advantages of Robotics in Industrial Production

The adoption of robotics in industry offers considerable benefits. One of the most obvious is the improvement in efficiency and productivity. Robots can work 24 hours a day without interruption, with constant speed and precision, significantly increasing production output.

Product quality is also enhanced. Robots reduce the risk of human error and ensure consistency that even the most skilled workers cannot match. This precision is crucial in industries where margins for error are minimal.

In addition, robotics contributes to better safety in the workplace. By taking over dangerous or repetitive tasks, robots reduce the risk of accidents and musculoskeletal disorders among workers. This translates into fewer sick days and an increase in employee well-being.

Challenges and Ethical Considerations

Despite its many benefits, industrial robotics presents challenges. One of the main ones is the management of change in work environments. The integration of robots often requires a restructuring of processes and training of employees, who must learn to interact and coexist with these new machines.

Autonomous robots equipped with AI circulate in a logistics warehouse, optimizing transportation and inventory management.

Ethical issues and the impact on employment are also major concerns. As robots replace some human tasks, it is essential to consider the implications for the workforce. However, the creation of new jobs in the areas of programming, maintenance and supervision of robots is a positive aspect.

Finally, the security of robotic systems is a growing concern, especially in terms of cybersecurity . With the increase in connectivity and intelligence of robots, it is crucial to protect these systems against cyberattacks and failures, to ensure the security of industrial processes and data protection.

Innovations and Future Trends in Industrial Robotics

The field of industrial robotics is constantly evolving, with innovations pushing the boundaries of what is possible. The integration of artificial intelligence (AI) and machine learning has opened new avenues, allowing robots to become more autonomous, adaptive, and intelligent. These advances enable robots to make real-time decisions, optimize production processes, and adapt to changing environments, which is the foundation for accelerating the transition to Industry 5.0 .

An autonomous electric pallet truck circulates in a production area to deliver the products to be assembled.

Cobotics, or human-robot collaboration , is another major trend. Unlike traditional industrial robots, cobots are designed to work in harmony with humans, sharing workspace and complementing human skills. This approach offers more flexibility and opens the way to more diverse applications.

Autonomous mobile robots (AMRs) also represent a significant innovation. Capable of moving autonomously in a work environment, these robots bring a new dimension to logistics and materials management. They can navigate autonomously, transport goods and perform logistics tasks without human intervention.

Looking to the future, advancements such as soft robotics, the integration of advanced sensors, and improved human-machine interfaces will continue to transform the industry. These innovations offer exciting possibilities for smarter, more integrated automation.

Case Studies: Success of Robotics in Industry

The impact of robotics in industry is best illustrated through real-world case studies. These examples highlight how robots are transforming industrial operations, offering valuable lessons and insights into the future.

A notable example is a large automotive company that integrated robots into almost every step of its production line. These robots not only improved production efficiency and quality, but also played a key role in reducing costs and improving worker safety.

In the electronics industry, one manufacturer used robots to automate the assembly of small components. This integration increased production accuracy and speed, while reducing waste and errors.

Another case study comes from the pharmaceutical industry, where robots are used for the handling and packaging of sensitive products. Here, robotics has not only improved efficiency, but also ensured a high level of compliance and quality, essential in this sector.

These case studies demonstrate the positive and transformative impact of robotics across various industrial sectors. They provide tangible examples of how robotic technology can be applied to improve production processes, increase efficiency and maintain high standards of quality and safety.

Conclusion

Industrial robotics has come a long way since its early applications. Today, it is at the heart of industrial transformation, playing a crucial role in optimizing production processes, improving product quality, and ensuring worker safety. Innovations in robotics, ranging from the integration of artificial intelligence to cobotics, are opening up new possibilities for industries of all sizes and sectors.

However, with these advancements come challenges and responsibilities. Companies must navigate a rapidly evolving technology landscape, while considering ethical implications and the impact on the workforce. Employee training and re-education, organizational change management, and robotic system safety are critical aspects to consider.

Looking to the future, it is clear that robotics will continue to play a leading role in industrial innovation. Technological advances promise to make robots even smarter, more flexible, and more integrated into industrial operations. By embracing these changes and addressing these challenges, industries can take full advantage of the potential of robotics to transform production in a sustainable and efficient way.

Annexes

For in-depth information, check out sites like IEEE Xplore , ScienceDirect , and Google Scholar .

Courses and tutorials are available on Coursera , edX , and MIT OpenCourseWare .

Join professional communities such as the International Federation of Robotics (IFR) , the IEEE Robotics and Automation Society , and the Robotic Industries Association (RIA) .

Discover Digital Factory's recommended solutions for industrial automation and robotics.