Subscribe to our newsletter

Be the first to know about the latest solutions

Digital factory

J8/ Model — Calculation and monitoring of OEE Excel 2025 - Industry 4.0 - 1k Users

J8/ Model — Calculation and monitoring of OEE Excel 2025 - Industry 4.0 - 1k Users

Couldn't load pickup availability

The OEE Calculation Software changes how industries monitor and enhance their performance. It tracks and analyzes vital data like downtime, production rates, and scrap rates. This gives real-time insight into production performance and enables quick decision-making to fix issues and boost productivity. OEE is a crucial tool for Industry 4.0.

To know more about OEE, check out “ All you need to know about OEE (Overall Equipment Effectiveness) ”

This document is available on the Excel editor: a direct access link will be sent to you after purchase.

Compatible with Microsoft Excel 2016 and later.

Does not contain macros, works on several simultaneous workstations via Excel Online, it is easily adaptable and modifiable according to your specific needs.

|

💡 Easy to use Immediate deployment |

⏱️ Instant delivery After order |

📞 Support Assistance when needed |

Steps to Monitor and Improve Your OEE (Overall Equipment Effectiveness)

Step 1: Install a Data Collection Device

Step 2: Connect Your Data to Excel

Step 3: Update Reports

Step 4: Implement an Action Plan (PDCA)

Structure and Key Components

1. A OEE monitoring table

-

Dashboard with dynamic filters that integrate essential KPIs for monitoring OEE, performance, quality, and availability. To learn more about calculating OEE, check out an example on ( A Complete Guide to Calculate and Improve your OEE)

2. A Pareto Availability loss analysis dashboard

- Analysis of the main causes of availability loss using dynamic filtering by team, machine, and timeline

3. A Pareto dashboard for analyzing scrap rates

- Analysis of the main causes of scrap using dynamic filtering by team, machine, and timeline

4. Availability Rate Monitoring by Machine

- Tracking of the Top 8 Machines with the Most Downtime in a Recent Period

5. Quality Rate Monitoring by Machine

- Tracking of the 8 critical Machines Generating scraps in a Recent Period

6. Data Entry Sheets

- Category: Category entry sheet (teams, stations, causes)

- Batch: Batch entry sheet to record daily production campaigns: Date, team, required production time, good parts to produce objectives, good parts produced

- Scraps: Entry sheet per team and per day of the quantities of good, reworked and rejected parts with the causes

- Stoppages: Team entry sheet for production stoppages and the causes and types of stoppage (scheduled stoppage, breakdown, organized malfunction, series change, non-quality)

7. Tracking the main causes of rejects and stoppages

- Summary: OEE and quality monitoring graph by daily batch and team

- Monthly review: OEE monitoring graph and cumulative batch quality per month to analyze trends over a longer period

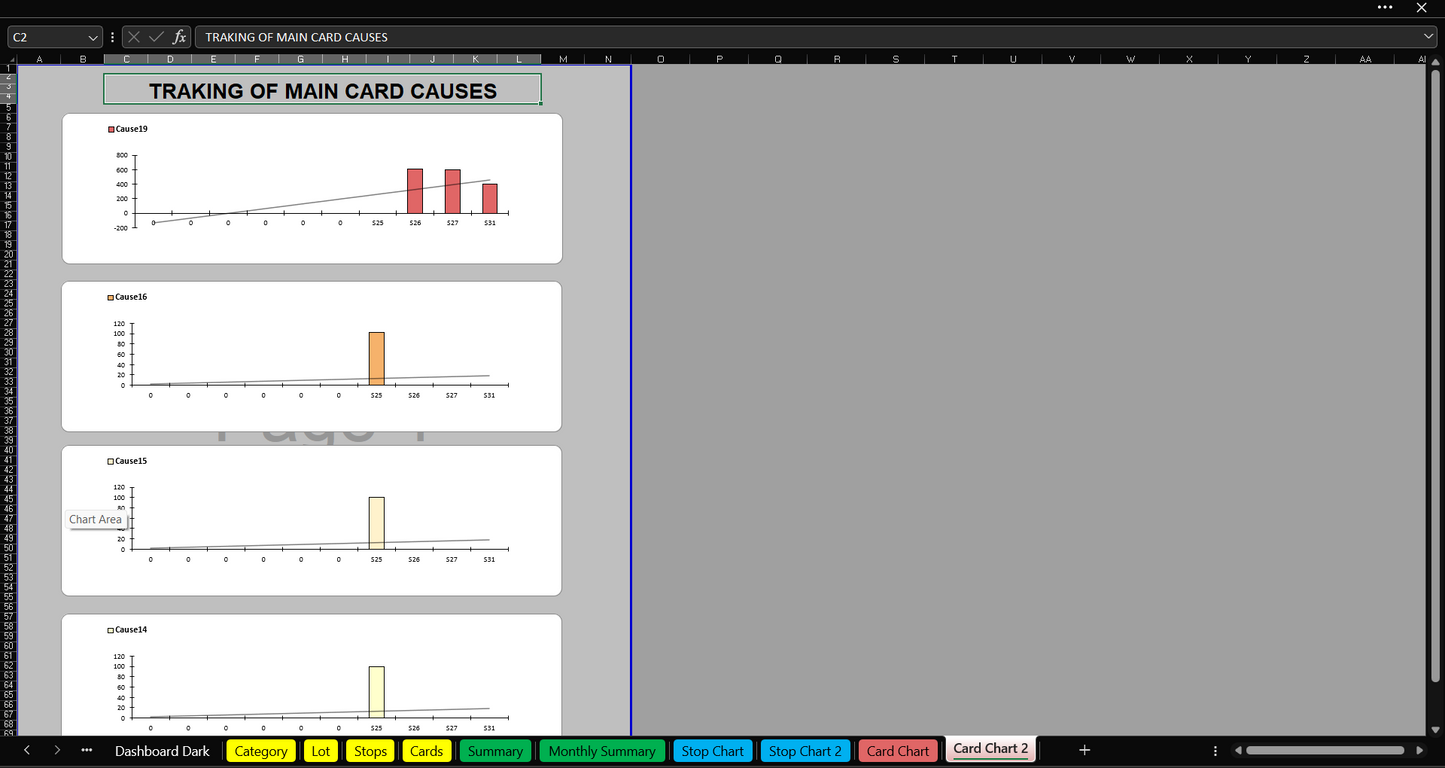

8. Pareto tracking of main causes of scraps and stoppages

- Shutdowns Graph: Pareto graph of major shutdowns over the last 4 weeks

- Stops Graph 2: Time tracking graph of main stops

- Cartons Chart: Pareto chart of major scraps and reworks over the last 4 weeks

- Scraps graph: Time tracking graph of main scraps

9. Others

- Pivot tables for personalized analyses,

OEE monitoring: Methodology and Applications

To guarantee optimized monitoring, you will need to check these few steps:

- Enter the stations of the line, the causes of rejects and the causes of stops

- Fill the databases: production campaign, stoppages and scraps

- View and analyze the performance indicators of your production line

- Implement actions to improve the performance of your equipment

Use this tool to deploy TPM (Total Productive Maintenance) simply, quickly and efficiently. It is a resource used by leaders in the automotive industry, essential in today's competitive industrial context. Save time and resources and focus on improving your performance.

Simplified tracking software

This Excel model for OEE calculation is easily deployed within your organization and does not require any particular technical skills for its use. However, it is strongly recommended to provide a demonstration for managers and operators, in order to facilitate your first steps in monitoring the OEE and understanding this indicator.

Optimization and Advanced Management of Production

For optimal monitoring, we support you step by step in setting up a complete solution to integrate data from your existing ERP, MES , SCADA, etc. systems. This approach streamlines data entry for operators and enriches KPI analysis for managers, making it easier to evaluate improvement measures . To find out more about our support offers, do not hesitate to consult our support offers page and the functionalities of our OEE software.

🎯 Boost your production with this tool, used by leaders in the automotive industry. Save time and resources by aiming for operational excellence.

Key Features

- TPM deployment

- OEE tracking

- Quality report

- Availability tracking

- Pareto of causes

- Analysis and reporting

Industries

- Automotive

- Aerospace and defense

- Agri-food

- Pharmaceutical industry and medical devices

- Metallurgy and steel industry

- Paper and packaging

- Electronics and semiconductors

- Textiles and clothing

- Manufacturer

Compatibility

- Microsoft Excel

Share

- Access your product in 30 seconds: steps 👇

- Title

- Title

FAQs

What is OEE?

OEE is a key performance indicator used to measure production efficiency by taking into account availability, performance and quality.

How does OEE calculator software help industries?

The software collects and analyzes production data, such as downtime, production rates and scrap rates, enabling real-time visualization of performance and rapid decision-making to improve productivity.

What are the key components of the software?

- OEE monitoring and calculation dashboard

- Pareto performance loss analysis dashboard

- Pareto dashboard for scrap rate analysis

- Monitoring of availability rate per machine

- Monitoring of quality rates per machine

- Data entry sheets for stops and scraps

What are the steps to monitor and improve OEE?

Step 1: Install a data collection device

Step 2: Connect Data to Excel

Step 3: Update Reports to Analyze OEE

Step 4: Implement an action plan (PDCA)

Does the software work with Excel?

Yes, the Excel template for calculating OEE is compatible with Microsoft Excel 2016 and later versions. It does not contain macros and can work on several workstations simultaneously via Excel Online.

Do I need technical skills to use the software?

No, the software is designed to be easy to deploy and use without special technical skills. A demonstration is recommended for managers and operators.

How can this software help me deploy TPM (Total Productive Maintenance)?

By using this tool, you can view and analyze performance indicators, identify the main causes of losses, and implement actions to improve the performance of your equipment, thus facilitating the deployment of TPM.

Is the software suitable for existing systems (ERP, MES, SCADA)?

Yes, we offer support to integrate data from your existing systems to guarantee optimized monitoring of your production.

How can I access the software after purchase?

A direct access link to the Excel document will be sent to you after purchase.

Which industries can benefit from this software?

The software is used by leaders in the automotive industry and is essential for any company seeking to improve its production performance in a competitive industrial context.

I used this Excel OEE tracking template, and I must say it's both easy to use and very effective. It allows for detailed analysis of equipment performance by integrating operating times, downtime, and efficiency losses.

Easy to fill out and customize, pay attention to cell formats to avoid errors in the dashboards.

I've been deploying this tool for two weeks and am happy with it. It's easy to use and provides robust analysis results to develop improvement measures.

Very practical for monitoring the TRS, the databases are easy to complete, and the dashboards are very well designed to effectively monitor and analyze in depth the causes of problems.

powerful tool has completely transformed how we manage operations. Everything is intuitive and easy to apply. Tanks team

Subscription offers

Subscription - Access to Excel, Power BI and Ms project tutorials and models

Corporate Pack

- No renewal constraints

- Full access to all tutorials:

- MS Project: Planning, Resources

- Power BI: Data Preparation, Dashboards

- Power Automate: Workflow Automation

- Full access to all models:

- Project management, Operational efficiency, Lean,...

- Premium Dashboards Included

- Unlimited downloads

- Personal space included

- 30 minute support included

Monthly Subscription

- Full access to all tutorials:

- MS Project: Planning, Resources

- Power BI: Data Preparation, Dashboards

- Power Automate: Workflow Automation

- Full access to all models:

- Project management, Operational efficiency, Lean,...

- Premium Dashboards Included

- Unlimited downloads

- Personal space included

- 30 minute support included

Annual Subscription

- All the advantages of the monthly

- Save 36% compared to monthly

- Priority consultation with an expert

- Updates and new models every week

Recommendations

-

J8/ Model — Calculation and monitoring of OEE Excel 2025 ...

4.94 / 5.0

(32) 32 total reviews

Regular price From €159,00Regular priceUnit price / per€279,00Sale price From €159,00Sale -

J9/ Budget and Deliverables Tracking Template for Business

3.67 / 5.0

(6) 6 total reviews

Regular price From €59,00Regular priceUnit price / per€249,00Sale price From €59,00Sale -

J28/ Power Bi Project Management Template to download

4.0 / 5.0

(8) 8 total reviews

Regular price From €0,00Regular priceUnit price / per -

J27/ MS Project Gantt Planning Template to download

Regular price From €69,00Regular priceUnit price / per -

J10/ Project Management Excel Model for project managers

4.82 / 5.0

(11) 11 total reviews

Regular price From €49,00Regular priceUnit price / per€219,00Sale price From €49,00Sale -

J30/ Power BI Model - Risk Analysis (Amdec)

Regular price From €0,00Regular priceUnit price / per -

J7/ Model — Example FMEA Excel Process - Dashboard - RPN ...

4.44 / 5.0

(9) 9 total reviews

Regular price From €59,00Regular priceUnit price / per -

C1/ ebook: White Paper - From vision to action, the futur...

5.0 / 5.0

(4) 4 total reviews

Regular price €39,00Regular priceUnit price / per -

A2/ Advanced OEE Excel Template - Powerful Manufacturing ...

4.87 / 5.0

(23) 23 total reviews

Regular price From €99,00Regular priceUnit price / per€99,00Sale price From €99,00 -

A1/ Template - Budget and project deliverables tracking -...

5.0 / 5.0

(3) 3 total reviews

Regular price From €29,00Regular priceUnit price / per€59,00Sale price From €29,00Sale -

A9/ Model - Project Risk Analysis - Google Sheet/Excel

2.0 / 5.0

(1) 1 total reviews

Regular price €39,00Regular priceUnit price / per€149,00Sale price €39,00Sale -

A3/ Model - Process FMEA - Google Sheet/Excel - Pro

4.0 / 5.0

(1) 1 total reviews

Regular price From €29,00Regular priceUnit price / per€59,00Sale price From €29,00Sale -

A5/ Model - Dasboard KPI Planning MS Project - Excel - Go...

Regular price From €49,00Regular priceUnit price / per -

A5/ Excel FMEA Template - Google Sheet/Excel - Basic

3.67 / 5.0

(3) 3 total reviews

Regular price €0,00Regular priceUnit price / per -

C2/ Model — OEE Dashboard - Production Tracking - Excel T...

4.0 / 5.0

(3) 3 total reviews

Regular price From €49,00Regular priceUnit price / per€99,00Sale price From €49,00Sale -

A6/ Template — Machine risk analysis — Google Sheet/Excel

Regular price €499,00Regular priceUnit price / per -

A8/ Model — Maintenance instructions - Example User Manua...

Regular price From €39,00Regular priceUnit price / per -

A4/ Model — Suppliers assessment — Google Sheet/Excel

5.0 / 5.0

(1) 1 total reviews

Regular price From €9,00Regular priceUnit price / per€29,00Sale price From €9,00Sale -

J6/ Model — Free Excel Production Monitoring File: Exampl...

3.0 / 5.0

(2) 2 total reviews

Regular price €0,00Regular priceUnit price / per -

J11/ PDF — TRS - Definition, calculation, benefits and im...

Regular price €0,00Regular priceUnit price / per -

J12/ PDF — Industry 5.0: Definition, technology, advantag...

Regular price €0,00Regular priceUnit price / per -

J13/ Maintenance Management Excel Model (CMMS)

5.0 / 5.0

(1) 1 total reviews

Regular price From €99,00Regular priceUnit price / per -

J29/ Power BI Model - TRS (Overall Earnings Ratio) Monito...

5.0 / 5.0

(1) 1 total reviews

Regular price From €0,00Regular priceUnit price / per -

J14/ 5S Excel Model: Checklist, Audit and Control for Ind...

Regular price €0,00Regular priceUnit price / per -

J15/ Advanced DMAIC Model for your Lean Six Sigma Project...

Regular price €0,00Regular priceUnit price / per

Any questions?

Contact form

blog posts

View all-

How to reduce the administrative costs of a com...

Introduction to Business Cost Reduction Reducing business costs is essential to maximizing profitability. Accounting, logistics, human resources: the tasks involved are essential, but also costly and time-consuming. However, it is...

How to reduce the administrative costs of a com...

Introduction to Business Cost Reduction Reducing business costs is essential to maximizing profitability. Accounting, logistics, human resources: the tasks involved are essential, but also costly and time-consuming. However, it is...

-

Improve your project management with the Kanban...

Introduction Businesses are facing unprecedented challenges when it comes to project management. Client expectations are rising, deadlines are shrinking, and project complexity is constantly increasing. Faced with these challenges, traditional...

Improve your project management with the Kanban...

Introduction Businesses are facing unprecedented challenges when it comes to project management. Client expectations are rising, deadlines are shrinking, and project complexity is constantly increasing. Faced with these challenges, traditional...

-

How to boost innovation?

Introduction Innovation is no longer a simple competitive advantage: in a context marked by the constant evolution of technologies and customer expectations, also with the acceleration towards industry 4.0 ,...

1 commentHow to boost innovation?

Introduction Innovation is no longer a simple competitive advantage: in a context marked by the constant evolution of technologies and customer expectations, also with the acceleration towards industry 4.0 ,...

1 comment