Subscribe to our newsletter

Be the first to know about the latest solutions

Digital factory

A2/ Advanced OEE Excel Template - Powerful Manufacturing Dashboard

A2/ Advanced OEE Excel Template - Powerful Manufacturing Dashboard

Couldn't load pickup availability

In an industrial context where efficiency and productivity are paramount, managing and monitoring the performance of production units becomes a complex and essential task. To meet this challenge, implementing an effective monitoring system is not only necessary but crucial for operational success. The spreadsheet presented here is specifically designed to meet these needs, offering a complete solution for performance monitoring of a production unit, whether it consists of a single or multiple workstations. This systematic approach allows for real-time monitoring of various aspects of production and quick identification of areas needing attention to optimize processes and increase overall efficiency.

🎯 Boost your production with this tool, used by leaders in the automotive industry. Save time and resources by aiming for operational excellence.This document is available on Google Sheets and Excel editors: a direct access link will be sent to you after purchase.

This document does not contain macros, making it easily adaptable and modifiable according to your specific needs.

|

💡 Easy to Use Immediate Deployment |

⏱️ Instant Delivery After Ordering |

📞 Support Assistance When Needed |

Manufacturing Dashboard : Structure and Key Components

1. A manufacturing dashboard

- A Dashboard incorporating essential KPIs for quality monitoring and OEE (Overall Equipment Effectiveness) tracking.

2. Data Entry Sheets

- Category: Data entry sheet for categories (teams, stations, causes)

- Batch: Data entry sheet for recording daily production campaigns

- Cartons: Data entry sheet for quantities of good, touched up, and rejected pieces

- Stops: Data entry sheet for production stops

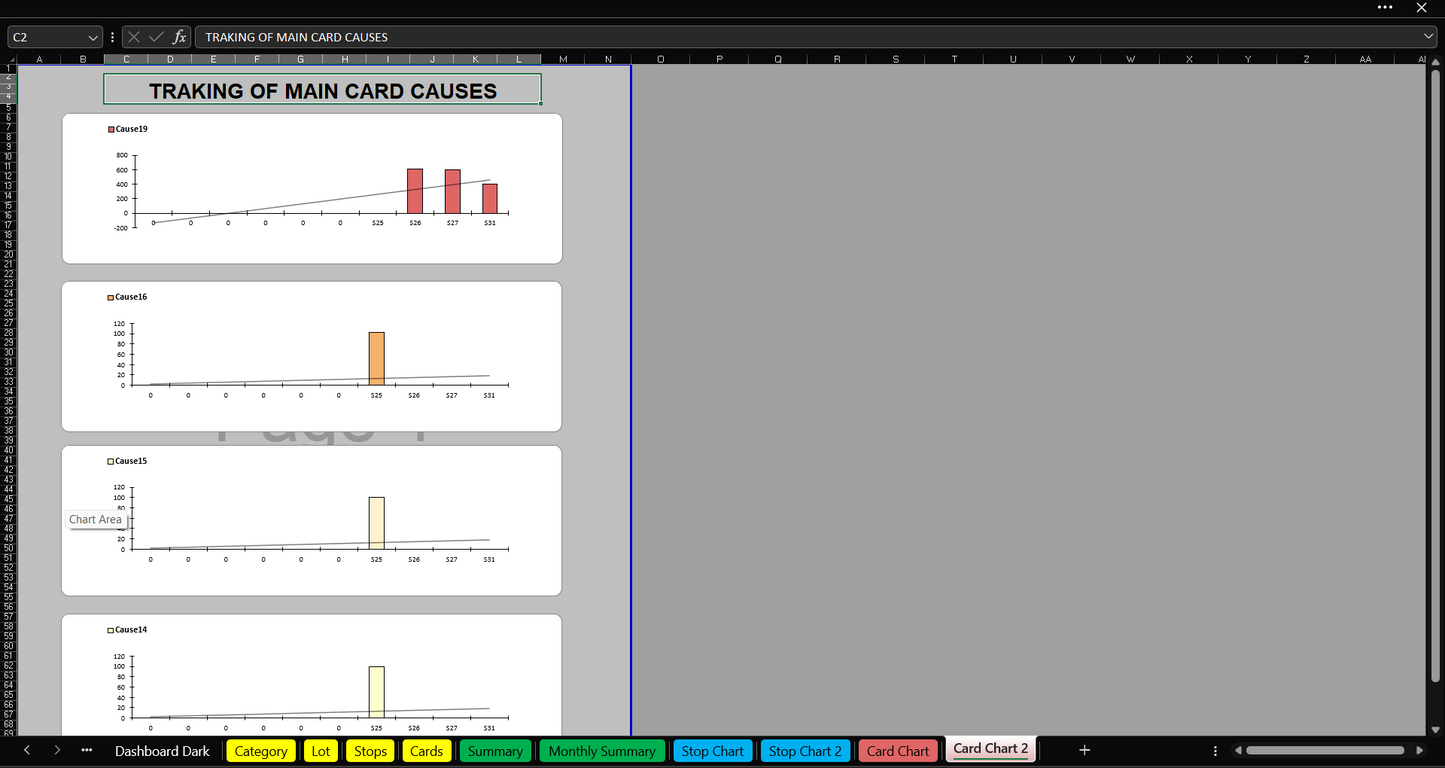

3. Tracking Major Causes of Scrap and Stops

- Report: Chart tracking batches to visualize the evolution of your production performance

- Monthly Report: Chart tracking runs by month to analyze longer-term trends

4. Pareto Analysis of Major Causes of Scrap and Stops

- Stop Chart: Pareto chart of major stops over the last 4 weeks

- Stop Chart 2: Temporal tracking chart of major stops

- Carton Chart: Pareto chart of major scraps and touch-ups over the last 4 weeks

- Scrap Chart: Temporal tracking chart of major scraps

5. Others

- Pivot tables for customized analyses

OEE Reporting and Calculation: Methodology and Applications

To ensure optimized monitoring, you will need to follow these steps:

- Enter the line stations, scrap causes, and stop causes

- Fill in the databases: production campaigns, stops, and scraps

- Visualize and analyze the performance indicators of your production line

- Implement actions to improve the yield of your equipment

Use this tool to deploy TPM (Total Productive Maintenance) in a simple, fast, and effective manner. It's a resource used by automotive industry leaders, indispensable in today's competitive industrial context. Save time and resources and focus on improving your performance.

🎯 Boost your production with this tool, used by automotive industry leaders. Save time and resources, aiming for operational excellence.

Advanced Production Management and Optimization

To ensure optimal tracking, we guide you step by step in implementing a comprehensive solution to integrate data from your existing ERP, MES, SCADA, etc. systems. This approach streamlines data entry for operators and enhances KPI analysis for managers, facilitating the evaluation of improvement measures. To learn more about our support offerings, feel free to visit our support offer page and discover the features of our OEE software.

Key Features

- TPM deployment

- OEE tracking

- Quality report

- Availability tracking

- Pareto of causes

- Analysis and reporting

Compatibility

- Microsoft Excel

- Google Sheet

Share

- Access your product in 30 seconds: steps 👇

- Title

- Title

FAQs

What is OEE?

OEE is a key performance indicator used to measure production efficiency by taking into account availability, performance and quality.

How does OEE calculator software help industries?

The software collects and analyzes production data, such as downtime, production rates and scrap rates, enabling real-time visualization of performance and rapid decision-making to improve productivity.

What are the key components of the software?

- OEE monitoring and calculation dashboard

- Pareto performance loss analysis dashboard

- Pareto dashboard for scrap rate analysis

- Monitoring of availability rate per machine

- Monitoring of quality rates per machine

- Data entry sheets for stops and scraps

What are the key components of this OEE tracking model?

- Production monitoring dashboard with essential KPIs

- Data entry sheets (shifts, stations, causes, batches, quantities of parts, stops)

- Batch tracking graphs to visualize performance evolution

- Pareto charts to analyze the main causes of scraps and stoppages

- Pivot tables for personalized analyzes

Does the software work with Excel?

Yes, the Excel template for calculating OEE is compatible with Microsoft Excel 2016 and later versions. It does not contain macros and can work on several workstations simultaneously via Excel Online.

Does the software work with Excel and Google Sheets?

Yes, the template is compatible with Microsoft Excel 2016 and later, as well as Google Sheets. It does not contain macros and can work on several workstations simultaneously via Excel Online.

How can this software help me deploy TPM (Total Productive Maintenance)?

By using this tool, you can view and analyze performance indicators, identify the main causes of losses, and implement actions to improve the performance of your equipment, thus facilitating the deployment of TPM.

Is the software suitable for existing systems (ERP, MES, SCADA)?

Yes, we offer support to integrate data from your existing systems to guarantee optimized monitoring of your production.

How can I access the software after purchase?

A direct access link to the Excel or Google Sheets document will be sent to you after purchase

Which industries can benefit from this software?

The software is used by leaders in the automotive industry and is essential for any company seeking to improve its production performance in a competitive industrial context.

What support is available if needed?

We offer support for any questions or problems you may encounter while using the software. Our team is available to help you maximize the efficiency of your production monitoring.

Grâce à ce fichier Excel, j’ai une vision claire de la performance de mes équipements.

This tool has helped me to easily measure, analyze, and improve production efficiency. I highly recommend it!

Parfait pour suivre les indicateurs de performance. C’est simple, bien présenté, et ça me permet de voir l'évolution.

This tool has really made a difference in our factory. It simplifies tracking our production progress, helps us manage tasks better, and improves overall efficiency.

J'utilise ce modèle Excel depuis un mois et nous commençons déjà à voir des impacts sur l'amélioration des performances des machines, mais aussi sur l'implication du personnel. Je suis satisfait des résultats.

Subscription offers

Subscription - Access to Excel, Power BI and Ms project tutorials and models

Corporate Pack

- No renewal constraints

- Full access to all tutorials:

- MS Project: Planning, Resources

- Power BI: Data Preparation, Dashboards

- Power Automate: Workflow Automation

- Full access to all models:

- Project management, Operational efficiency, Lean,...

- Premium Dashboards Included

- Unlimited downloads

- Personal space included

- 30 minute support included

Monthly Subscription

- Full access to all tutorials:

- MS Project: Planning, Resources

- Power BI: Data Preparation, Dashboards

- Power Automate: Workflow Automation

- Full access to all models:

- Project management, Operational efficiency, Lean,...

- Premium Dashboards Included

- Unlimited downloads

- Personal space included

- 30 minute support included

Annual Subscription

- All the advantages of the monthly

- Save 36% compared to monthly

- Priority consultation with an expert

- Updates and new models every week

Recommendations

-

J8/ Model — Calculation and monitoring of OEE Excel 2025 ...

4.94 / 5.0

(32) 32 total reviews

Regular price From €159,00Regular priceUnit price / per€279,00Sale price From €159,00Sale -

J9/ Budget and Deliverables Tracking Template for Business

3.67 / 5.0

(6) 6 total reviews

Regular price From €59,00Regular priceUnit price / per€249,00Sale price From €59,00Sale -

J28/ Power Bi Project Management Template to download

4.0 / 5.0

(8) 8 total reviews

Regular price From €0,00Regular priceUnit price / per -

J27/ MS Project Gantt Planning Template to download

Regular price From €69,00Regular priceUnit price / per -

J10/ Project Management Excel Model for project managers

4.82 / 5.0

(11) 11 total reviews

Regular price From €49,00Regular priceUnit price / per€219,00Sale price From €49,00Sale -

J30/ Power BI Model - Risk Analysis (Amdec)

Regular price From €0,00Regular priceUnit price / per -

J7/ Model — Example FMEA Excel Process - Dashboard - RPN ...

4.44 / 5.0

(9) 9 total reviews

Regular price From €59,00Regular priceUnit price / per -

C1/ ebook: White Paper - From vision to action, the futur...

5.0 / 5.0

(4) 4 total reviews

Regular price €39,00Regular priceUnit price / per -

A2/ Advanced OEE Excel Template - Powerful Manufacturing ...

4.87 / 5.0

(23) 23 total reviews

Regular price From €99,00Regular priceUnit price / per€99,00Sale price From €99,00 -

A1/ Template - Budget and project deliverables tracking -...

5.0 / 5.0

(3) 3 total reviews

Regular price From €29,00Regular priceUnit price / per€59,00Sale price From €29,00Sale -

A9/ Model - Project Risk Analysis - Google Sheet/Excel

2.0 / 5.0

(1) 1 total reviews

Regular price €39,00Regular priceUnit price / per€149,00Sale price €39,00Sale -

A3/ Model - Process FMEA - Google Sheet/Excel - Pro

4.0 / 5.0

(1) 1 total reviews

Regular price From €29,00Regular priceUnit price / per€59,00Sale price From €29,00Sale -

A5/ Model - Dasboard KPI Planning MS Project - Excel - Go...

Regular price From €49,00Regular priceUnit price / per -

A5/ Excel FMEA Template - Google Sheet/Excel - Basic

3.67 / 5.0

(3) 3 total reviews

Regular price €0,00Regular priceUnit price / per -

C2/ Model — OEE Dashboard - Production Tracking - Excel T...

4.0 / 5.0

(3) 3 total reviews

Regular price From €49,00Regular priceUnit price / per€99,00Sale price From €49,00Sale -

A6/ Template — Machine risk analysis — Google Sheet/Excel

Regular price €499,00Regular priceUnit price / per -

A8/ Model — Maintenance instructions - Example User Manua...

Regular price From €39,00Regular priceUnit price / per -

A4/ Model — Suppliers assessment — Google Sheet/Excel

5.0 / 5.0

(1) 1 total reviews

Regular price From €9,00Regular priceUnit price / per€29,00Sale price From €9,00Sale -

J6/ Model — Free Excel Production Monitoring File: Exampl...

3.0 / 5.0

(2) 2 total reviews

Regular price €0,00Regular priceUnit price / per -

J11/ PDF — TRS - Definition, calculation, benefits and im...

Regular price €0,00Regular priceUnit price / per -

J12/ PDF — Industry 5.0: Definition, technology, advantag...

Regular price €0,00Regular priceUnit price / per -

J13/ Maintenance Management Excel Model (CMMS)

5.0 / 5.0

(1) 1 total reviews

Regular price From €99,00Regular priceUnit price / per -

J29/ Power BI Model - TRS (Overall Earnings Ratio) Monito...

5.0 / 5.0

(1) 1 total reviews

Regular price From €0,00Regular priceUnit price / per -

J14/ 5S Excel Model: Checklist, Audit and Control for Ind...

Regular price €0,00Regular priceUnit price / per -

J15/ Advanced DMAIC Model for your Lean Six Sigma Project...

Regular price €0,00Regular priceUnit price / per

Any questions?

Contact form

blog posts

View all-

How to reduce the administrative costs of a com...

Introduction to Business Cost Reduction Reducing business costs is essential to maximizing profitability. Accounting, logistics, human resources: the tasks involved are essential, but also costly and time-consuming. However, it is...

How to reduce the administrative costs of a com...

Introduction to Business Cost Reduction Reducing business costs is essential to maximizing profitability. Accounting, logistics, human resources: the tasks involved are essential, but also costly and time-consuming. However, it is...

-

Improve your project management with the Kanban...

Introduction Businesses are facing unprecedented challenges when it comes to project management. Client expectations are rising, deadlines are shrinking, and project complexity is constantly increasing. Faced with these challenges, traditional...

Improve your project management with the Kanban...

Introduction Businesses are facing unprecedented challenges when it comes to project management. Client expectations are rising, deadlines are shrinking, and project complexity is constantly increasing. Faced with these challenges, traditional...

-

How to boost innovation?

Introduction Innovation is no longer a simple competitive advantage: in a context marked by the constant evolution of technologies and customer expectations, also with the acceleration towards industry 4.0 ,...

1 commentHow to boost innovation?

Introduction Innovation is no longer a simple competitive advantage: in a context marked by the constant evolution of technologies and customer expectations, also with the acceleration towards industry 4.0 ,...

1 comment